Boots not really in good shape

and I think a bump stop is missing too.

Boots are supposed to prevent dust to enter

the tight space between the shiny rod

and the rubber seal in the shock absorber.

164.0 Note the location of spring end.

Top and bottom

Parts bump stops there are some for Koni as well,

even polyeurethane ones

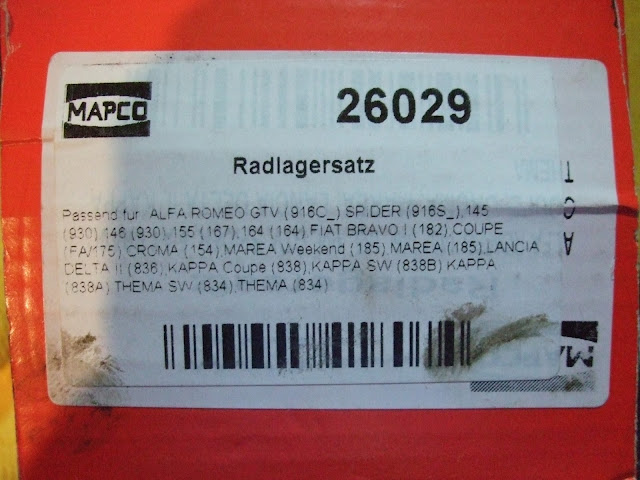

164.1 Sachs repair kit Shock core diameter 22 mm

Tools well there are many out there you need a good tool , these springs when compressed act ekcately like the springs in the pens you used to take apart in school on boring days , compress them and they might fly a considerabely distance...remember how easy they were to compress , their weight and the distance the flev.

164.3

You are going to need some really sturdy stuff this is the best I have ever had

164.4

For the top of the strut you need another tool a very loooong socket 22 mm open alloving you to stop the shiny rod to rotate this one sadly didnt work its way to big in outer diameter

164.5 top mount three bolts 13 mm 164.6 the not so right socket

164,7 So if you are out there to buy tools max outer dia. would be : 33 mm

Top mount upside down inner diameter of hole for shock nut shown

Damned Pain Arrrrrrgh.

164.8

This one fits perfectly sadly it comes without the opening that allows you tho fix the shockrod from spinning hence plan B a mole grip at the highest akcessible point on the rod.Top mount out of car to clearer illustrate

Torque 66 - 82 Nm. 164.9

Start at the top Top mount 13 mm ringspanner or long socket .

Torque 12 - 18 Nm. 164.10

Now the base of the strut is the original Boge , the Koni is insertet into that and fixed to it with a bolt at the bottom.

To loosen the bracket you once again need a breaker bar and a 17 mm socket. WD 40 might come in handy too.....

Torque 40 - 49 Nm. 164.11

Thes came of surpricingly easy , now remove the top mount before you remove these bolts completely or you will find it difficult to support the weight of the strut AND loosen the three nuts.

164.12 leave them the strut assembly is heavy.

pull them out when your foot is out of the way.

Secure the strut in a wise bottom bracket facing right or left or whatever you prefer , there are many many asymmetrical parts and you need to realign them.164.13

Be careful you might lose a hand or two. Church in Verona Italy

Put your spring compression tool on and squeeeeeeese.MAKE SHURE SEVERAL TIMES THAT THE HOOKS SPADES OR WHATEVER IS IN CONTACT WITH THE SPRING IS IN THE RIGHT PLACE . Here shown with the molegrip at the top of the shock rod.

Contactpoints at the spring Compressing tool and molegrip

164.14

Remove parts top to bottum here closeup of the molegrip position on the shockabsorber core, it really doesent leave any marks.

164.15

note the two screwdrivers pointing at the groove and the corresponding thing

at the green screwdriver.

Bump stop ready to be shortend

164.17

164.17

Whats left in the wise. A compressible rod.Some force is needed !!

164.18 164.19

That upon release returns

164.20

Boot and bump stop , Spring has lowered the car a lot so the bump stop needs shortening.

Box knife lubricated with silicone spray does the job.

164.21 164.22

Assemble boot and stop.

from below

groove and notch

apply silicon spray

164.23

Boot and stop on silicon spray eases it a lot.

Grease between rod and rubber seal

silicone based grease

164.24 164.25

And then on the lower bearing.

Remember orientation

Screwdriver tip at the recess for the start of the spring strut body still in same orientation as during disassembly.

164.26 close up botttom plate and spring 164.27

164.26 close up botttom plate and spring 164.27

align the upper plate and the top mount , the impression from the spring in the seal is clearly on the underside , this alignmentspot too.

164.28 164.29

Well since plan A was the proper strut socket and it didnt fit Mole grip again in position above the bump stop , you have to depress the boot and the bump stop.

molegrip on shock rod top 164.30

Im waiting for a new driveshaft hence the delay in putting it back on the car . Torque for the top mount 13 mm nuts : Lower Bracket bolts :

Well you could end up needing a pair of theese

164.31

Front trailing arm , front bush,despite the use of powerflex it doesent look right , we need to give it a closer look its powersteering oil all ower the place .

Torque 29 - 32 Nm.

164.32

You might as well be prepared for a lot of time , pain and suffering again under you car

164.33

Trailing arms usally comes with the two inner OEM rubber bushes preinstalled , some even with the outer ball joint.

Here hub assembly and brakes onto the outer ball joint.

164.34

Do you really want polyeurethane bushes , well at least the rear bush is reasonable easy to replace. Start your drillbit your stanley knife ad your Dremel 164.35

Clean the aluminum casing , this is NOT clean 164.36

Final touch grinding paper onto the dremel and you end up with this GREEESE 164.37

SQUEECE

Do not panic if the bush tilts on it way through the aluminum casing,just continue 164.38

The aluminum casing jumps up like this

164.39

Continue ,steel tube in GREEESE 164.40

This powerflex is asymmetrical

FRONT 164.41 REAR

164.42

FRONT REAR

164.43

Its time for some cake

I´ll be back.

William Lutken